μReflow Oven with MicroPython & LVGL

A PID-controlled reflow oven controller built for the ESP32 using MicroPython and the LVGL graphics library. It features a touch-screen interface for selecting solder profiles, real-time temperature monitoring via thermocouple amplifiers, and remote configuration via FTP.

Overview

The μReflow Oven is a sophisticated DIY solution for reflow soldering, designed to transform a standard kitchen oven or heating plate into a precision electronics manufacturing tool. Built specifically for the ESP32 microcontroller, the project leverages MicroPython for its logic and the LittlevGL (LVGL) library to provide a rich, touch-enabled graphical user interface.

This project is an evolution of the Adafruit EZ Make Oven, heavily modified to support PID (Proportional-Integral-Derivative) temperature control. This ensures that the heating profile closely follows the specific requirements of various solder pastes, preventing component damage and ensuring high-quality solder joints.

Hardware Architecture

The system is designed around widely available and affordable components, making it accessible for hobbyists and professional engineers alike. The core hardware stack includes:

- ESP32 Development Board: Acts as the central controller running MicroPython.

- ILI9341 TFT Display: A 2.8-inch or similar screen with an integrated XPT2046 touch controller for user interaction.

- Thermocouple Amplifier: Supports both MAX31855 and MAX6675 modules for high-temperature K-type thermocouple sensing.

- Solid State Relay (SSR): Rated for at least 10A to safely switch the oven’s heating elements.

- Passive Piezo Buzzer: Provides audible alerts during the reflow process.

Advanced PID Control

Unlike simpler on/off controllers, this project implements a full PID algorithm to manage the heating curve. The PID controller is highly configurable via a config.json file or directly through the GUI. To handle the unique challenges of reflow profiles—which are dynamic curves rather than static setpoints—the firmware includes advanced features:

- Preheat Until: A threshold temperature where the oven stays at full power to reach initial temperatures quickly.

- Provisioning: A look-ahead parameter that allows the PID to react to the setpoint temperature X seconds in advance, improving responsiveness to the changing curve.

- Overshoot Compensation: Specific logic to reduce temperature spikes when transitioning between profile stages.

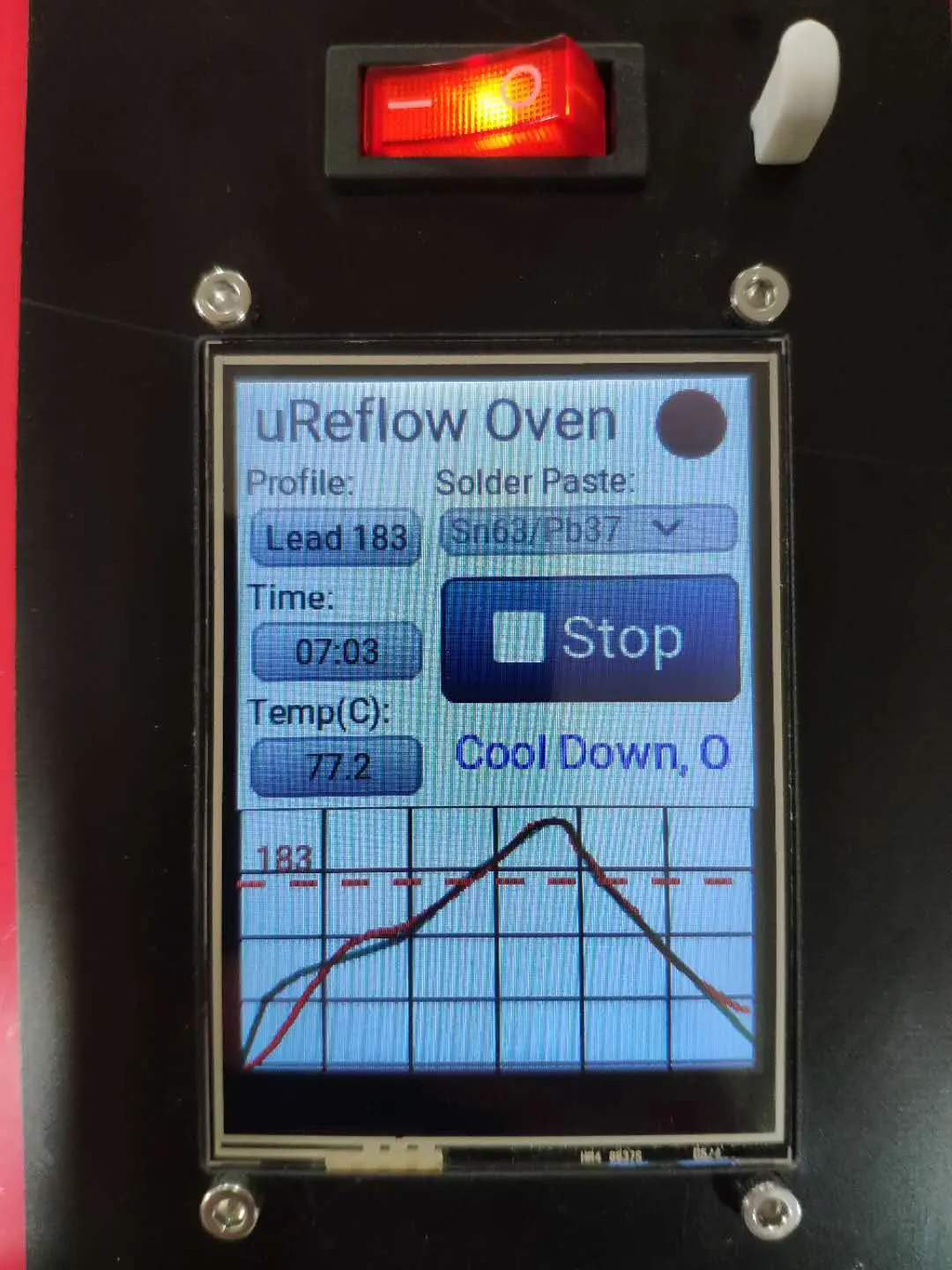

User Interface and Experience

The GUI, built with LVGL, offers a professional experience on a small screen. Upon first boot, users are guided through a touch screen calibration process. The main interface allows users to select from various solder paste profiles (e.g., Leaded vs. Lead-Free) via a dropdown menu. Once a profile is selected, the ideal temperature curve is displayed visually.

For users with unique requirements, custom solder profiles can be added by placing JSON files in the profiles directory. The system also includes a built-in FTP server. By connecting to the ESP32’s WiFi access point, users can edit configuration files and upload new profiles wirelessly using a standard FTP client like FileZilla.

Technical Implementation and Setup

The project is organized into a MAIN folder containing the MicroPython scripts and configuration files. Key configuration is handled in config.json, where users define GPIO pins for the SPI display, touch controller, SSR, and sensors.

PID Tuning Tips

For optimal performance, the project documentation suggests a specific tuning workflow:

- Set

previsioningandovershoot_compto zero to establish a baseline. - Use a small

kp(e.g., 0.1) and a largekd(e.g., 300) to minimize early-stage overshooting. - Gradually increase

kito ensure the actual temperature reaches the peak required during the ‘reflow’ stage. Note that the integration component (ki) is specifically hard-coded to activate only during the reflow stage to prevent wind-up during preheating.