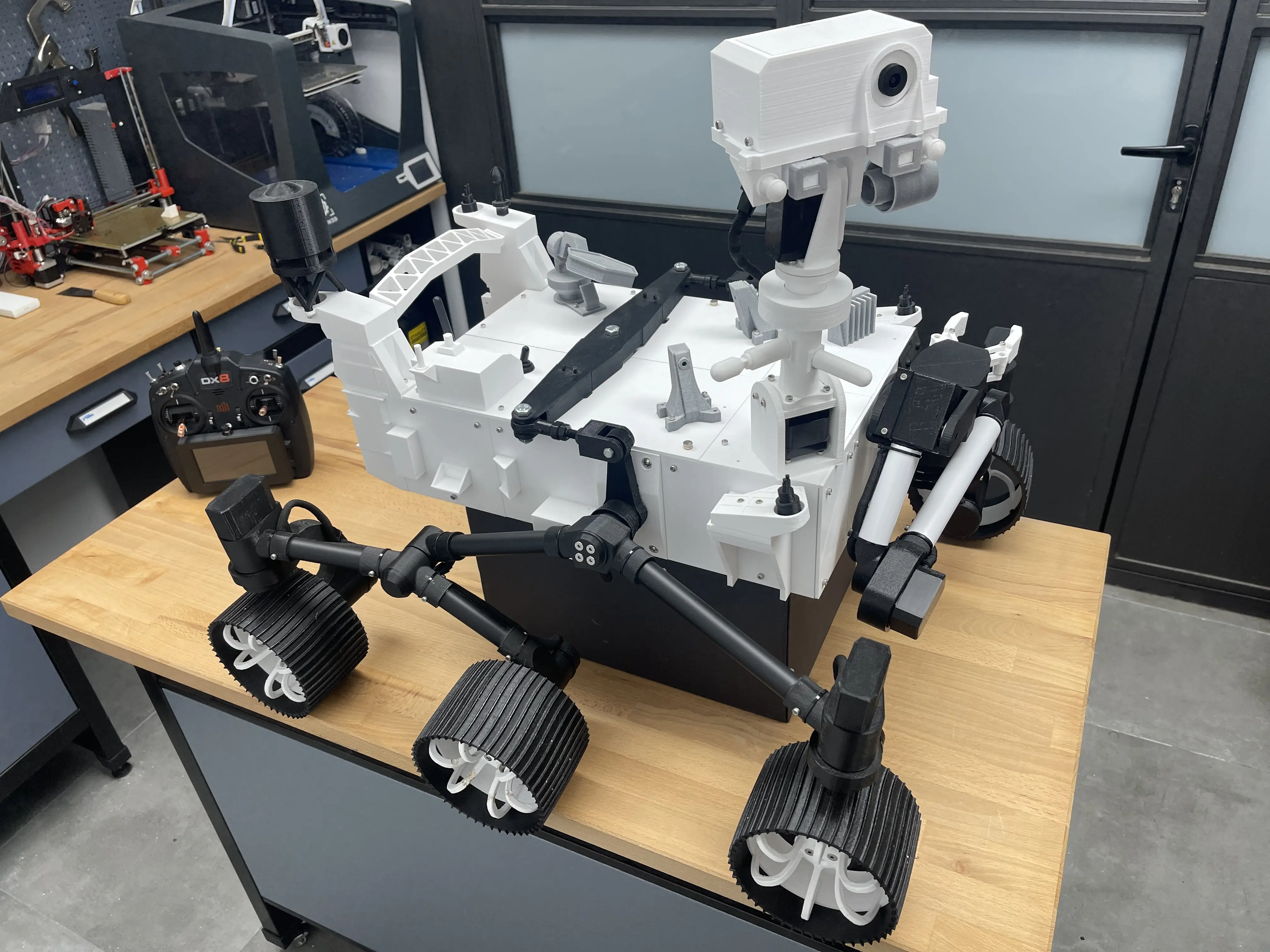

OpenRover Robotic Platform

A modular, open-source 3D-printed robotic platform modeled after NASA's Perseverance rover. It employs a distributed control system using Arduino Mega, ESP32-S3, and Raspberry Pi Zero 2W, featuring a custom LVGL-based touchscreen interface and a Flask-powered web dashboard for remote monitoring.

Overview

The OpenRover project is a sophisticated, open-source robotic platform designed as a functional 3D-printed replica of NASA’s Perseverance Mars rover. Developed as a final computer engineering degree project, it serves as a comprehensive educational resource for learning about hardware integration, distributed systems, and embedded software development. Unlike many DIY robotics projects that rely on a single controller, OpenRover utilizes a multi-processor architecture to handle its various complex subsystems, ranging from motor control to high-level web connectivity.

System Architecture & Modules

The platform is organized into three primary functional modules, each leveraging the strengths of different development boards:

Central Rover Module

At the heart of the rover is an Arduino Mega. This board is responsible for the low-level hardware abstraction, managing the 6-wheel drive system (including 4 steerable wheels), the 4-axis robotic arm, and the tiltable camera head. It also interfaces with environmental sensors to monitor temperature, humidity, pressure, and altitude, while handling radio frequency (RF) communication for remote operation.

Remote Control & Touchscreen Module

User interaction is handled by a custom-built remote control unit. This module features an ESP32-S3 dedicated to driving a touchscreen interface designed with SquareLine Studio and the LVGL library. An auxiliary Arduino Nano within the same unit handles the reading of RC channel values, battery monitoring, and RF signal transmission, offloading these real-time tasks from the UI processor.

Camera & Webserver Module

For high-level telemetry and vision, a Raspberry Pi Zero 2W is housed within the rover’s head. This board generates its own WiFi network and hosts a Flask-based web dashboard. It provides a live video feed from the onboard camera and displays real-time status values, allowing for remote monitoring from any browser-enabled device.

Key Features

- Advanced Locomotion: A 6-wheel drive platform with 4-wheel steering, enabling complex maneuvers like 360º stationary turns.

- Robotic Articulation: Includes a 4-axis foldable robotic arm with a functional gripper and a dual-axis rotary head.

- Sophisticated UI: A custom embedded touchscreen interface for selecting operation modes (Driving, Arm Control, Head Control) and viewing telemetry.

- Environmental Monitoring: Integrated sensors for atmospheric data and battery health for both the rover and the remote.

- Web Integration: A dedicated dashboard for video streaming and status monitoring via WiFi.

Technical Implementation

The software stack is as diverse as the hardware. The microcontrollers (Arduino and ESP32) are programmed using the PlatformIO IDE within the Arduino Framework. The touchscreen UI leverages the LVGL (Light and Versatile Graphics Library) to provide a responsive, modern user experience on the embedded display. On the Raspberry Pi side, Python and Flask are used to bridge the gap between the embedded hardware and web-based user interfaces.

Build & Extensibility

Building an OpenRover is a significant undertaking, estimated at approximately 140 hours of assembly and wiring, plus roughly 400 hours of 3D printing. The project is designed to be modular and extensible; the author encourages builders to “take it to the next level” by adding computer vision for autonomous navigation, recording robotic arm sequences, or designing custom PCBs to replace the point-to-point wiring. The codebase is distributed across several specialized repositories linked via Git subtrees, ensuring that each module can be developed or improved independently.